1. Hydrostatic Test is based on ASME B31.3.

2. Pipe plugs are 100% Hydrostatic Test at 15 bar with a holding time of 10 minutes.

3. Pipe plug is designed to be used for a maximum water depth of 80 m.

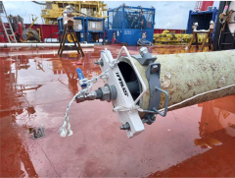

4. Safety ring clamp is provided for diver operated pipe plug type for the safety safe guard.

5. Internal area of pipe shall be cleaned from debris before insert pipe plug for better efficiency.

6. Pipe plug products are not designed for pressure from cyclic loads or dynamic loads.

7. Maximum Operating Pressure shall be specified by client with consideration of all potential load cases.

8. ROV-operated pipe plug is optional. The technical data are similar to diver operated pipe plug.

9. Sacrificial anodes are installed onto pipe plug, if pipe plug requires to be left in place for the desired service life.

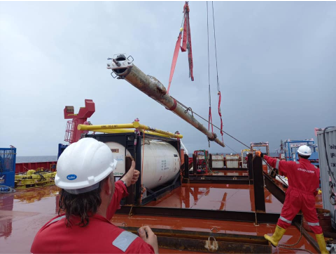

This pipe plug type with proven records of successful & safe offshore operations with major E&P companies.

2. Pipe plugs are 100% Hydrostatic Test at 15 bar with a holding time of 10 minutes.

3. Pipe plug is designed to be used for a maximum water depth of 80 m.

4. Safety ring clamp is provided for diver operated pipe plug type for the safety safe guard.

5. Internal area of pipe shall be cleaned from debris before insert pipe plug for better efficiency.

6. Pipe plug products are not designed for pressure from cyclic loads or dynamic loads.

7. Maximum Operating Pressure shall be specified by client with consideration of all potential load cases.

8. ROV-operated pipe plug is optional. The technical data are similar to diver operated pipe plug.

9. Sacrificial anodes are installed onto pipe plug, if pipe plug requires to be left in place for the desired service life.

This pipe plug type with proven records of successful & safe offshore operations with major E&P companies.